Kirti welding machines are manufactured using latest technology and precision engineering that makes them economical to run & simple to use and operates consuming optimum electricity.

These are specially designed for high speed production job to meet vast needs of industry.

A variety of electrodes and tools can be fitted to make the machine suitable for Spot Welding, Projection Welding, Cross Wire Welding, Electro Brazing, Hot Riveting, Electro Forging and Upsetting & many more applications.

Kirti Machines Are Preferred For

Our manufacturing processes make machines more

Sturdy and Reliable

- 10 mm Thick body (TATA steel)

- Machine body made sturdy by CNC bending and welding

- Laser cut body gives interchangeability of assembly parts

- Cylinder Head & Brass elbow Machining on HMC

- Powder Coated body

Modular design and quick connect wiring harness make

Easy Maintenance & Troubleshooting

- Machines have Quick Connect Wiring Harness with snap on connectors

- Can easily remove - controller, thyristor and other assembly parts

- It also helps in fault finding

Controlled Weld Ecosystem

Machine Interlocks & Real time Current Monitor to make every weld perfect

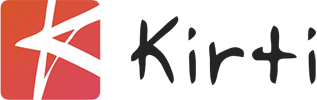

We developed POKA-YOKE system for every important parameter like Water Pressure, Air Pressure, Current, Dressing count and Temperature control for Thyristor & Transformer.

The Tower Lamp gives Audio & Visual alarm if value of any of the parameter increases or decreases from the respective ‘Set Value‘. The Machine stops operating and starts only when the parameter resumes to the Set Value.

This Poka-Yoke system makes sure that welding process is done only when all the parameters are idol thus making welding error free.

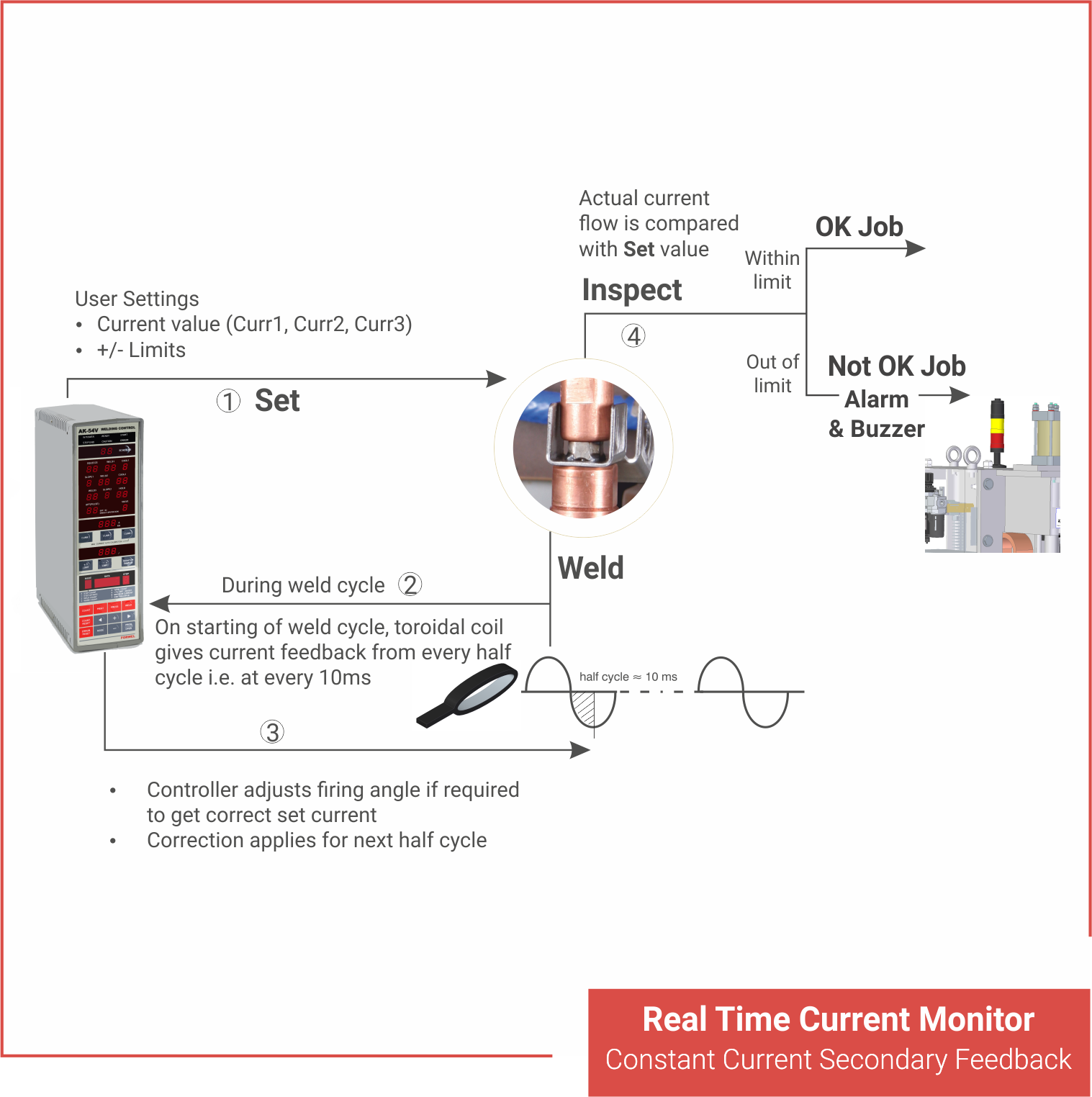

Controller supplies stable welding current by secondary feed-back constant current method. Thus maintaining the current as per 'Set Value' throughout the welding process.

Benefits for Nut Projection Welding -

- The welded nut withstands 2 times breaking torque that of standard specification

- No Retapping

- No Co2 Tagging

- Minimizes Rework, Reduces Cost

- Avoids frequent Destruction Testing

- No adverse effects on the Threads and thus responds to go-no go test positively