Features

Perfect for achieving best resultsControlled Weld Ecosystem

To make each weld perfect

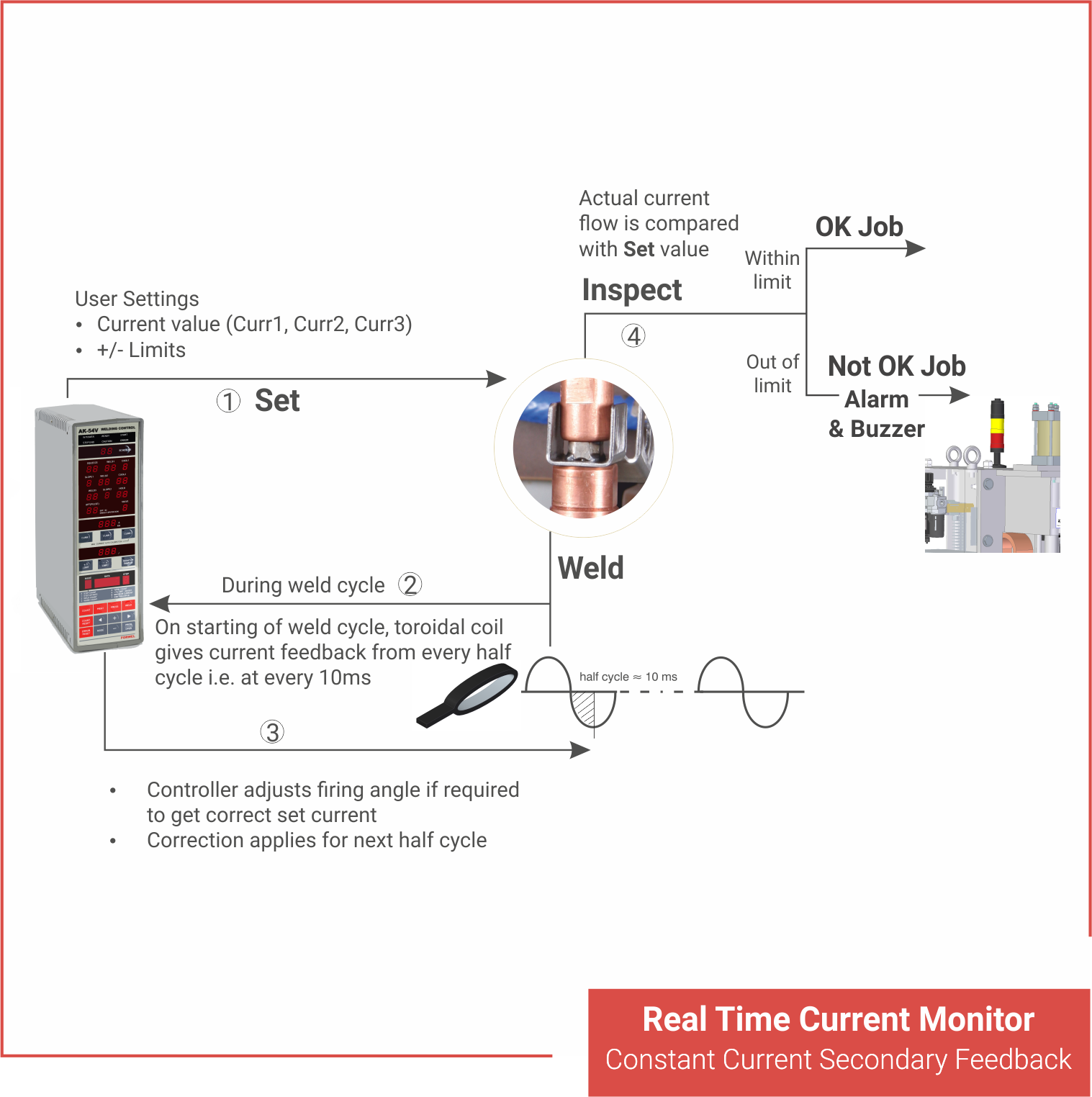

Controller supplies stable welding current by secondary feed-back constant current method. Thus maintaining the current as per 'Set Value' throughout the welding process.

Benefits for Nut Projection Welding -

- The welded nut withstands 2 times breaking torque that of standard specification

- No Retapping

- No Co2 Tagging

- Minimizes Rework, Reduces Cost

- Avoids frequent Destruction Testing

- No adverse effects on the Threads and thus responds to go-no go test positively

Money Back Guaranty

You can now buy and test our Resistance Welding Controller without any worries as we assure you 100% money back guarantee.

You can place an order for Resistance Welding Controller i.e Spot Welding Controller and on 100% receipt of payment you will get your Controller which you can evaluate for 30 days. If our Controller fails to satisfy you, You will get your complete money back.You can now buy and test our Resistance Welding Controller without any worries as we assure you 100% money back guarantee.

Terms & Conditions:

- On return of the Resistance Welding Controller we shall check for the intigrity and operation. If it is satisfied and the return is in time, you will get 100% money back.

- No questions will be asked.

- If the Resistance Welding Controller is found damaged on return, service and repair charges are applicable.

| Type | Controller | Control Power | Valve Output | Mounting | Networking Capability |

|---|---|---|---|---|---|

| Secondary Feedback Resistance Welding Controller | AK-54 | 220v AC | Relay Output | Vertical & Horizontal | Rs485/ RS232 |

| Secondary Feedback Resistance Welding Controller | SK-54 | 90~220v AC | Relay Output | Vertical & Horizontal | Rs485/ RS232 |

| Voltage Compensation Type Resistance Welding Controller | SK-24 | 90~220v AC | SSR Output (220vAC) | Vertical & Horizontal | Not Available |

| Three Phase DC Controller | AK-32 | 220v AC | Relay Output | Vertical | Not Available |

- Parts of different thickness can be weld in the same welding sequence by calling Multiple Weld Schedules

- 15 weld schedules can be set

- External schedule select

- Controller has self-adjustment for maximum current

- Data acquisition software - optional

- Prints of welding schedules, real-time & of errors

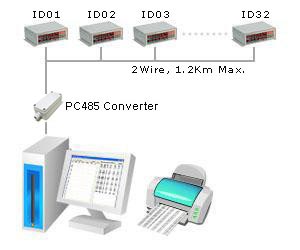

- By using Welding Data Logger(Fcom_V2.3) Software Welding Data can be collected from each AK54 Controller at real time and the collected data can be stored by Excel file at computer.

-

One PC can be linked to maximum 32 units of AK54.- Weld Current Data and Schedule Data can be requested to each of AK54, then the data can be seen and printed.

-

Weld Schedule can be changed by PC.

-

When welding defects is occurred, event monitoring is available and time and weld current data can be checked easily at real time.

-

Opto-Isolated RS485 Card (Option) is installed inside of AK54.

-

PC and AK54 is connected by 2 electric wires and the length is maximum 1.2 Km

- Horizontal and vertical dimensions for AK-54( Horizontal and Vertical model) - 288mm x 207mm

- Weight - 1 kg

- Networking of upto 32 machines (optional)

- 9 Steppers / Linear Stepper

- 2 Pressure Valve Output and 7_Operations

- Current 1, 2, 3 Monitor with High/Low Monitor

- 3 easy-to-operate counters to aid in systematic quality control and tipdressing schedules

- PC and RS485 Network Interface (Optional)

- Toroidal Coil 450mm or 600mm

- Remote Cable 485 Converter

- Remote Control Panel

- 485/232 Card